The peroxide value (POV) is defined as the reactive oxygen contents expressed in terms of milliequivalents (meq) of free iodine per kilograms of fat. It is determined by titrating iodine liberated from potassium iodide with sodium thiosulphate solution. The method of determination of peroxide value in fats and oils will be studied in this article.

Peroxides are the fundamental components of the breakdown products that give fat its rancid flavors. Peroxide concentrations are a sign of oxidation in the early phases of lipid degradation. Due to a rise in peroxide degradation, this index becomes less reliable as deterioration increases. Fresh oils are those that have POV values much below 10 meq/kg. As soon as the POV reaches between 20 and 40 meq/kg, a rancid taste can be detected.

Principle

The sample is treated in solution with acetic acid and a suitable organic solvent, then treated with a potassium iodide solution. The liberated iodine is titrated using a standard sodium thiosulfate solution.

Procedure for Determining Peroxide value in

fats and oils

Apparatus required

- Balance machine

- Funnel, beaker, hot plate

- Burette with stand

- Measuring cylinder

- Erlenmeyer flask

- Spatula, pipette, test tube, filter paper

Procedure

1. Chemical preparation

Acetic acid: chloroform (3:2)

- Measure 90ml conc acetic acid and pour into a reagent flask.

- Measure 60ml of chloroform and pour into a same reagent flask and mix well.

- Shake the flask to mix the chemical.

- Now, the mixture of acetic acid and chloroform at 3:2 is now ready to use.

1 % starch solution

- Measure 50ml distilled water and take in a 100ml beaker, placed the beaker in hot plate and heat the water to boil.

- Take Weigh 0.5g of starch solution and transfer the weighted starch into the boiling water.

- Now, stire the solution with a clean glass rod while boiling to dissolve the starch in water.

- Continue boiling and stirring until a transparent solution obtained.

- After dissolving the starch filter the solution immediately by using a filter paper.

- Now, after the 30min transfer the filtrate solution in a suitable container and 1% starch solution is ready to use.

0.01N Sodium Thiosulfate

- Dissolve 0.25g of sodium thiosulfate in 80ml distilled water and add 0.02g of sodium carbonate, then after mix well by shaking.

- Heat the solution, if necessary to dissolve sodium thiosulfate completely and cool at room temperature.

- Add enough distilled water to make the final 100ml volume.

- Standardize the prepared solution with potassium dichromate.

Saturated potassium iodide solution

- Take 2ml of distilled water into the test tube and add KI into the test tube until the undissolved KI is left at the bottom.

- Now, saturated KI is ready to use.

2. Sample preparation

- Take approximately, 10-12g of oil sample in an Erlenmeyer flask and note the sample weight.

- Measure 30ml of acetic acid – chloroform mixture and pour the mixture into the flask and shake to mix with sample.

- Add 1ml of saturated potassium solution and shake for 1 min.

- Now, add 30ml of distilled water and shake for 1 min to mix well.

3. Titration

- Take 0.01N sodium thiosulfate in a burette and note the initial burette reading.

- Add 0.5ml of 1% starch solution as indicator.

- Mix by rotating and shaking the flask and start titration.

- Continue titration until the black colour is removed completely.

- Now, stop titration when the solution is turned into white.

- Note the final burette reading.

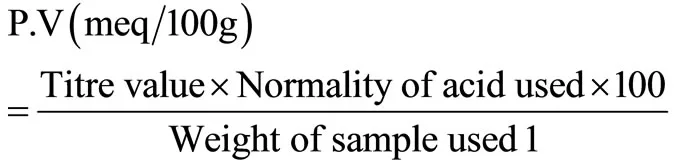

4. Calculation

Peroxide value =

Where,

- V is volume of Na2S203

- N is a normality of Na2S203

- WS is a sample weight

Importance of determining peroxide value in

fats and oils

- A measurement of the degree of oxidation in fats and oils is the peroxide value (PV). It is one of the most used methods for determining the freshness and quality of fats and oils. PV measures the number of peroxides, which are formed as a result of the oxidation of fats and oils.

- PV is mostly used to assess the oxidative stability of fats and oils. A high degree of oxidation, as indicated by high PV values, can result in the development of off flavor, rancidity, and decreased nutritional value. As such, PV is often used to monitor the shelf life and quality of fats and oils, particularly those used in food production.

- PV values are also used to evaluate the efficacy of antioxidants and other additives in preventing oxidation in fats and oils.

- Fats and oils’ peroxide concentration plays an important role for assuring the safety, quality, and nutritional value of food products as well as for enhancing the effectiveness of various formulations and additives.

Learn more

Difference between Acid value and peroxide value

| Acid value | Peroxide value |

| Measures the quantity of free fatty acids in a sample. | Measures the quantity of peroxide compounds in a sample. |

| Expressed as the amount of potassium hydroxide (KOH) needed to neutralize one gram of the sample’s free fatty acids. | Expressed in milliequivalents of active oxygen per kilogram of sample. |

| Indication of the degree of hydrolysis and oxidation of fats and oils. | Indication of the degree of oxidation of fats and oils. |

| Utilized to evaluate the quality of edible fats and oils. | Used to evaluate the stability and freshness of oils and fats. |

| High acid values indicate hydrolysis, rancidity, or fat and oil deterioration. | High peroxide values indicate that oils and fats include primary oxidation products. |

| Based on titration using a standard alkali solution. | Measured using a standard iodine solution during titration. |