What is Fermentation?

Fermentation is an enzyme catalyzed, metabolic process whereby organisms convert starch or sugar to alcohol or an acid anaerobically releasing energy. The study of fermentation is called “zymology”.

Using microorganisms like bacteria, yeast, or fungi, food fermentation involves converting carbohydrates into alcohol or organic acids. Since ancient times, it has been a natural process used to make a variety of foods, including cheese, yogurt, beer, wine, bread, sauerkraut, kimchi, and many more. Foods that have undergone fermentation develop their different flavor, texture, and aroma as a result of the microorganisms’ consumption of the food’s carbohydrates, which they break down into simpler compounds. These simpler compounds include lactic acid, acetic acid, carbon dioxide, and alcohol. Additionally, fermentation offers a number of beneficial health benefits, including improved immunity and improved digestion.

Process of Food fermentation

By utilizing microorganisms like bacteria, yeasts, or fungi to transform carbohydrates into organic acids or alcohol, the fermentation process of food provides a variety of delicious and nutritious foods. General overview of the fermentation process:

Selection of Raw Materials

The selection of raw materials is the first stage in the fermentation process. Different basic ingredients, such as milk for yogurt or cabbage for sauerkraut, may be utilized depending on the type of food being fermented.

Preparation of Raw Materials

The raw materials are prepared by washing, chopping, or grinding them as needed.Additionally, before fermentation, some raw materials may require cooking or pasteurization.

Bacterial Inoculation

Inoculating the raw materials with the proper bacteria is the next step. This can be performed by introducing a starting culture or by allowing the raw materials’ natural microorganisms start the fermentation process on their own.

Fermentation

The inoculated raw materials are then allowed to ferment at a specific temperature and for a specific period of time. Depending on the kind of microorganisms utilized, the bacteria consume the carbohydrates in the raw materials during fermentation and convert them into simpler chemicals such lactic acid, acetic acid, carbon dioxide, and alcohol.

Flavour Developments

As the fermentation process continues, microorganisms develop a variety of flavor compounds that give the fermented food a unique taste and aroma.

Packaging and Storage

The fermented food is packaged and kept in storage once the fermentation process is complete. Food may need to be refrigerated or kept at room temperature depending on the type.

Depending on the type of food being fermented, the length of the fermentation process and the particular microorganisms utilized might change. For example, yogurt normally takes few hours to ferment, but sauerkraut might take many weeks. The flavor and nutritional value of the fermented food can also be affected by the type of microorganisms that is utilized. Overall, the process of food fermentation provides a number of health advantages as well as providing a natural and efficient approach to preserve and improve the flavor of different foods.

Chemical process of fermentation

The chemical process of fermentation is an anaerobic process (meaning it occurs in the absence of oxygen) that allows microorganisms to generate energy and produce different end-products. Particular end products produced, as well as the flavor and nutritional value of the fermented food, might vary depending on the kind of microorganisms involved and the specific parameters of the fermentation process (such as temperature, pH, and nutrients).

Microorganisms like bacteria, yeasts, or fungi use the chemical process of fermentation to convert carbohydrates into organic acids, alcohol, and/or gases. Here is a general overview of the chemical process of fermentation:

Glycolysis

Glycolysis, which takes place in the cytoplasm of the bacterium, is the first stage of fermentation. In this step, the carbohydrate glucose is converted into pyruvate (a three- carbon molecule). A small amount of ATP (energy) is also produced as a result of this process.

Formation of organic acids, alcohol or gases

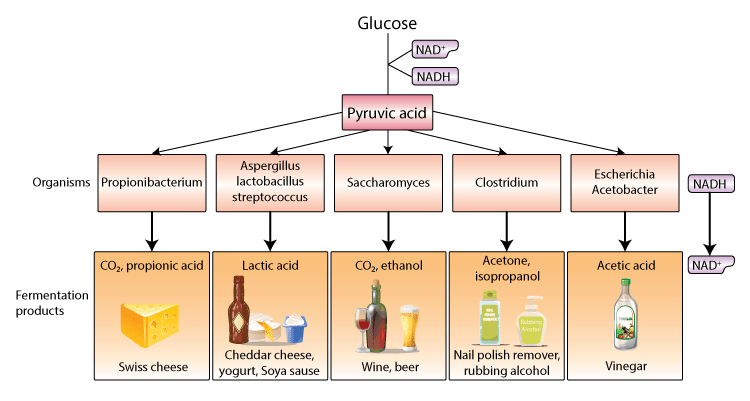

Depending on the particular microorganisms involved, the pyruvate is converted into different end products in the following step of fermentation. For example, yeast converts pyruvate into ethanol (alcohol) and carbon dioxide, whereas lactic acid bacteria convert it into lactic acid. Gases like hydrogen and methane are also produced by some microbes.

Regeneration of NAD+

In the glycolysis phase, NAD+ is oxidized, which results in the production of NADH during fermentation. NAD+ must be regenerated in order for glycolysis to take place. This happens through an anaerobic respiration process known as fermentation, in which NADH is converted back into NAD+ using the fermentation’s byproducts.

Overall, in fermentation, the first process is the same as cellular respiration, which is the formation of pyruvic acid by glycolysis where net 2 ATP molecules are synthesized. In the next step, pyruvate is reduced to lactic acid, ethanol or other products. Here NAD+ is formed which is re-utilized back in the glycolysis process.

Types of Fermentation

There are several kinds of fermentation, and each one is characterized by the kind of microorganisms used and the products that are produced. The most common types of fermentation are listed below:

Lactic Acid Fermentation

Pyruvate, which is produced during glycolysis, turns into lactic acid. NADH is used to produce NAD+. This process is facilitated by the enzyme lactate dehydrogenase. This type of fermentation produces curd from milk due to the Lactobacillus bacteria. Lactic acid is produced by muscles during vigorous activity when there is insufficient oxygen supply. It builds up in the cells and causes fatigue.

Lactic acid bacteria, that convert carbohydrates into lactic acid, carry out this type of fermentation. Fermented foods including yogurt, kefir, sauerkraut, and pickles are made using this method.

Alcoholic Fermentation

This is used in the industrial production of wine, beer, biofuel, etc. The end product is alcohol and CO2. Acetaldehyde is produced when pyruvic acid breaks down, and CO2 is released. The next stage involves turning acetaldehyde into ethanol. Additionally produced from NADH and used in glycolysis is NAD+. This form of fermentation is carried out by yeast and certain bacteria. These processes are catalyzed by the enzyme’s pyruvic acid decarboxylase and alcohol dehydrogenase.

Acetic Acid Fermentation

Acetic acid bacteria carry out the fermentation process that converts ethanol into acetic acid. Vinegar is made using this method. It is a two steps process:

The first stage involves utilizing yeast to anaerobically produce ethyl alcohol from sugar.

Using acetobacter bacteria, ethyl alcohol is further oxidized to produce acetic acid in the second stage. Alcohol is converted to acid by microorganisms in an aerobic process.

Butyric Acid Fermentation

In this process, Glycolysis first converts sugar into pyruvate, which is then further oxidized by the oxidoreductase enzyme system to produce H2 and CO2 and the compound acetyl-CoA. Butyric acid is produced by further reducing acetyl-CoA. This type of fermentation produces an energy production that is comparatively greater. Three ATP molecules are produced.

Certain bacteria carry out the fermentation of butyric acid, converting carbohydrates into butyric acid and other organic acids. Fermented foods like kimchi and several kinds of cheese are produced using this method.

Propionic Acid Fermentation

Propionibacterium are responsible for propionic acid fermentation, which converts lactic acid into propionic acid and carbon dioxide. Certain kinds of cheese, including Swiss cheese, are made using this method.

Mixed Acid Fermentation

Some bacteria carry out the process of mixed acid fermentation, which results in the production of a variety of organic acids, including lactic acid, acetic acid, propionic acid, and others. Fermented foods like pickles and sauerkraut are made using this method.

Application of fermentation

In the food sector as well as in other industries like medicine and production of energy, fermentation has a wide range of uses. Here are a few of the most common applications for fermentation:

Food production

Many different forms of food, including dairy products like yogurt and cheese, fermented vegetables like sauerkraut and kimchi, alcoholic drinks like beer and wine, and many more, are produced through fermentation. Foods may be preserved by fermentation as well as have their flavor, texture, and nutritional value increased.

Biomedical Application

Antibiotics, vaccines, and other therapeutic agents are only a few of the medications that are produced through fermentation. Many of these products are produced using microbial fermentation processes.

Biofuels

Biofuels like ethanol and butanol, which may be utilized as alternative energy sources, are made by fermentation. These biofuels may be made from a range of renewable feedstocks, including cellulosic biomass, sugarcane, and corn.

Bioremediation

Environmental contaminants, such as oil spills and other hazardous waste, can be cleaned up through fermentation. Utilizing fermentation methods, microorganisms that may breakdown these harmful substances are grown before being used to clean up polluted areas.

Industrial Application

The production of enzymes, organic acids, and other industrial compounds are only a few of the industrial uses for fermentation. It is also used in the production of animal feed, as fermentation can enhance the nutritional value of certain feedstocks.

Limitation of Fermented foods

While fermentation has many applications and benefits, there are also some limitations associated with this process. Here are some of the most common limitations of fermented food:

High sodium content

Fermented foods can be high in sodium due to the salt used in the fermentation process.Fermented food consumption may need to be restricted in those with high blood pressure or other medical disorders that call for a low-sodium diet.

Risk of contamination

Since fermentation is a natural process, many factors, such as temperature, humidity, and the kinds of microorganisms used, might have an effect. Foods that have been improperly fermented run the risk of becoming contaminated with harmful bacteria like Listeria or Salmonella.

Limited nutrient availability

Food nutrient content can change as a result of fermentation. While certain nutrients may be improved others can be reduced or made less readily available to the body for absorption.

Acidity

Fermented foods like pickles and sauerkraut can have a high acid content. Too much acid consumption might cause stomach pain or even damage tooth enamel.

Allergies

Some people may be sensitive to the yeasts or molds that are involved in the fermenting process. This can cause allergic reactions ranging from mild to severe.

References

- https://www.vocabulary.com/dictionary/fermentation

- https://www.healthline.com/nutrition/fermentation#benefits

- https://byjus.com/neet/types-of-fermentation/

- https://www.britannica.com/science/asymmetric-synthesis

- https://www.biologyonline.com/dictionary/fermentation

- https://sciencing.com/5-uses-fermentation-10015326.html

- https://www.ncbi.nlm.nih.gov/books/NBK234679/