Milk, a rich and complex fluid produced by mammals’ mammary glands, serves as a vital source of nourishment for their offspring. Packed with essential nutrients, hormones, growth factors, and immunological components, milk plays a pivotal role in sustaining life. Its production, known as lactation, is carefully regulated by hormones like prolactin and oxytocin, stimulating synthesis, secretion, and let-down of milk. Depending on the species and lactation stage, milk composition varies, encompassing water, carbohydrates (lactose), proteins (casein and whey proteins), lipids, vitamins, minerals, and trace elements. However, throughout the manufacturing, processing, and distribution processes, milk and milk products are susceptible to contamination from various sources. Poor milking sanitation, environmental pollutants, and udder illnesses in cows can introduce harmful bacteria and microbes, posing contamination risks. Proper handling, storage, and packaging are essential to prevent spoilage and preserve milk quality. Refrigeration and other preservation techniques, such as pasteurization and sterilization, play a crucial role in extending the shelf life of milk and milk products.

In this comprehensive guide, we delve into the intricacies of milk and milk product contamination, spoilage, prevention, and packaging methods, offering valuable insights into maintaining the integrity of this precious liquid for safe consumption and enhanced preservation.

Contamination of Milk and Milk Product

Milk and milk products can be contaminated from a variety of sources throughout the manufacturing, processing, and distribution processes. Here are some common ways milk and milk products can get contaminated:

Contamination of Milk and Milkproducts On Farm:

- Poor milking sanitation can introduce bacteria and other microbes into the milk from the cow’s udder or unclean equipment.

- Environmental contamination, such as cows grazing in contaminated water, soil, or air, may occur in the presence of harmful substances or pathogens in milk.

- Cow health problems, particularly udder illnesses such as mastitis, can cause higher bacteria levels in milk, developing a contamination risk.

- Improper milk storage and handling on the farm, such as insufficient temperature control or the use of impure containers, may lead to milk contamination.

Contamination In Transit and at Manufacturing Level:

- The tanker’s truck, transfer pipelines, sampling equipment, and requirements at the market milk factory or other processing plant are all potential sources of contamination once milk is left on the farm.

- Bacteria can be found in pipes, vats, tanks, pumps, valves, and separators.

Spoilage of Milk and Milk Product

Milk is an excellent culture medium for different types of bacteria due to its high moisture content, almost neutral pH, and high microbial food content. Microorganisms influence the basic characteristics and properties of milk and milk products. Product problems are determined by the specific species and number of microorganisms used in pre- and post-processing. Most changes are related to smell, flavor, or consistency.

Refrigeration is the most effective way of extending the shelf life of milk and milk products; however, spoiling can occur at this temperature as well, caused by the growth of pseudomonas spp, Enterobacteriaceae, and gram-positive bacteria.

Gas Production:

Gas formation is usually accompanied by acid formation. Gas production is shown by foam on top of milk that is supersaturated with gas, gas bubbles stuck in curd, and floating curd containing gas bubbles. The most gas is produced by coliform bacteria and heterofermentative lactis.

Proteolysis:

The breakdown of milk proteins by microorganisms is generally accompanied by the development of a bitter taste due to certain of the released peptides. Proteolysis is promoted by low-temperature storage due to the destruction of lactic and other acids by heat, as well as the destruction of produced acid in milk by molds and film yeasts or the neutralization of acids by microorganism products. Actively proteolytic bacteria are found in the genera Micrococcus, Alcaligens, Pseudomonas, Proteus, Flavobacterium, and Serratia, as well as the genera Bacillus and Clostridium, which are spore formers.

Ropiness:

Ropiness and sliminess are common in market milk and cream. Bacterial ropiness is generated by slimy capsular material from the cells and usually occurs at low temperatures. As the acidity of the milk or cream increases, the ropiness normally diminishes. Surface ropiness and ropiness throughout milk are the two basic forms of ropiness. Surface ropiness is caused by Alcaligens viscolactis, and Ropiness throughout is caused by Enterobacter areogens and rarely Escherichia coli. Sources of bacteria causing ropiness are water, manure, utensils, and feed.

Change in Milk Fat:

Milk fat is decomposed by various bacteria, yeast, and molds.

Unsaturated Fatty Acid Oxidation:

Produces aldehydes, whereas ketones produce tallow smells and taste. Lipase enzymes hydrolyze butterfat into fatty acids and glycerols. Rancidity is produced by combining oxidation and hydrolysis. Lipase-forming bacteria are present in many bacterial species, including Pseudomonas, Proteus, Alcaligens, Bacillus, Micrococcus, Clostridium, and others.

Alkali Production:

Pseudomonas fluoresces and Alcaligens viscolactis. Production of ammonia from organic acids and urea results in alkali formation.

Flavor Changes in spoiled milk and milk products

- Clean: produced by Streptococcus lactics.

- Aromatic: by streptococci and aroma-forming Leuconostoc species.

Clean and aromatic flavors are desired in fermented milk products, but sharp flavors are undesirable.

- Bitter flavors: Results from proteolysis, lipolysis, or even fermentation of lactose.

- Burnt flavor: Streptococcus lactis and maltigens produce this flavor.

Color Changes in spoiled milk and milk products

- Blue milk: Pseudomonas syncyanea when grown with Streptococcus lactis.

- Yellow milk: Pseudomonas synxantha and species of Flavobacterium.

- Red milk: Serratia marcescens, Micrococcus roseus.

- Brown milk: Pseudomonas putrefactions.

Methods of Preservation of Milk and Milk Product

Removal of Micro-organisms:

It is difficult to efficiently eliminate organisms after they have entered milk. High-speed centrifugation eliminates 99% of bacteria’s spores and half of their vegetative cells, as well as some protein. This method is not widely employed in the commercial sector.

Use of Heat

Pasteurization:

Pasteurization is done with 3 methods.

- Low Temperature Long Time: the process of heating every particle of milk or milk products to at least 63°C and maintaining that temperature for at least 30 minutes.

- High temperature short time: when milk is pasteurized at 72°C for 15 seconds, followed by rapid cooling.

- Ultra-High Temperature: UHT processing keeps the milk at 138°C for at least 2 seconds.

Objective of Pasteurization

- To destroy pathogenic organisms that may be present in milk.

- To enhance the keeping quality of milk and milk product.

Sterilization

Sterilization can be accomplished by the use of heat, chemicals, irradiation, high pressure, filtration, or a combination of these methods.

Steam under Pressure

Evaporated milk is canned and then heated under pressure using steam. As a result, milk should be heated to 93 to 100°C or higher to destroy resistant bacterial spores. Sealed cans of evaporated milk are processed for approximately 115 to 118 minutes, yielding a commercially sterile product.

Use of Low Temperature

Most dairy products require the use of low temperature except canned milk and dry milk.

Refrigerated Milk:

- For the production of milk of good quality, it is essential to cool the milk after it is withdrawn from the cow.

- Raw milk for pasteurization must be chilled to 1°C or below within 2 hours after being drawn and held at that temperature until processed.

- Milk is chilled throughout storage on the farm, as well as in the truck or tank during delivery to the receiving station.

Freezing:

- Ice cream and other frozen dairy desserts are frozen as a part of the manufacturing process. They are stored at low temperatures in the frozen state, where microbial multiplication is impossible.

- Pasteurized whole milk has been frozen at about -28 to -29°C and stored at a frozen state.

Drying:

- Dry products are produced by eliminating varying percentages of water from whole and skim milk.

- Enough moisture is removed to inhibit organism development.

- Whole milk powder should not include more than 5% moisture.

Use of Preservatives

- Sorbic and propionic acid, or their salts, are authorized in cheese and yogurt to prevent mold development on their surfaces and extend their shelf life.

- They are also included in some hard cheeses and processed cheeses to avoid mold growth on the surface.

- Added sugar acts as a preservative in sweetened condensed milk.

- Hydrogen peroxide mixed with a light heat treatment is used for the pasteurization of milk to eliminate specific types of bacteria.

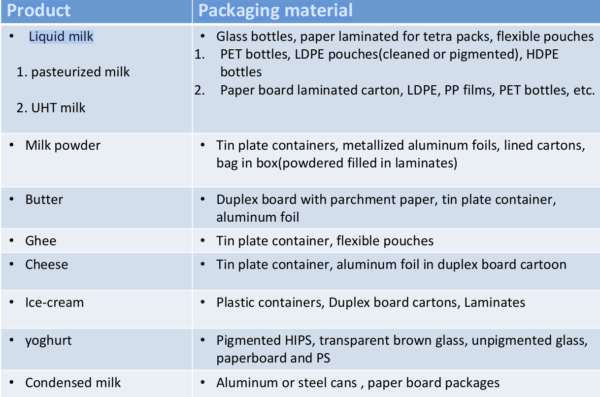

Packaging of Fat-Rich Dairy Product:

Roles of packaging materials:

- To protect the food from chemical enzymes.

- To make commercially sterile food.

- Can be manufactured in numerous sizes and shapes.

- Products have a longer shelf life.

- Easier to distribute and, therefore, have lower transportation costs.

- Heat-sealable and sterilizable.

- Easy opening and reclose.

- Easy to store.

Packaging for Pasteurized Milk

- Retail packaging: Pasteurized cream is packed in cartons and bottles for retail sale, with package sizes typically ranging from 100 to 1000ml. Multilayer materials may include an ethylene vinyl alcohol layer to increase the barrier qualities of plastic packaging for fresh cream. When the container is full, it is sealed with heat-sealed polyethylene or aluminum foil laminate.

- Bulk packaging: It might be utilized in catering. For bulk packing, polythene bags in plastic crates or cardboard boxes are typically employed. Package sizes in this scenario range from 2 to 25 liters.

Packaging for Sterilized Milk

- Tin cans and glass bottles are used to package retort sterilized cream. Sterilization occurs in a retort or hydrostatic sterilizer at temperatures ranging from 110 to 120°C for 10 to 20 minutes. Because greater quantities prevent heat transfer, the unit packing volumes must be relatively small (400ml).

Packaging of Butter

Packaging materials for butter should have excellent barrier properties such as:

- It should be moisture-proof and grease-proof.

- It should be impervious to light and also have good strength.

Some of the packaging materials used for butter packaging include parchment paper (also known as butter paper), wax-coated paper, cellophane, cardboard boxes, teakwood drums lined with food-grade plastic, aluminum foil laminates, and lacquered tin cans. Other types of packaging include plastic tubs thermoformed from white pigmented PVC with a tight-fitting lid of the same material.

Packaging of Milk Product

Milk powders readily take up moisture from the air, leading to a rapid loss of quality and caking or lumping. Therefore, packaging is chosen to provide a barrier to moisture, O2, and light. Milk powder is packed into either plastic-lined multi-wall bags or bulk bins and often packed under nitrogen gas to protect from oxidation, maintain flavor, and extend their keeping quality.

Packaging of Fermented Dairy Product

- Yogurt is the most well-known fermented milk product produced by lactic acid fermentation. Yogurt products come in a variety of packaging materials.

- The thermoformed HIPS in the shape of tiny cups or larger tubs, with either an aluminum foil/plastic laminate heat seal top or closure, is by far the most popular material in current usage for spoonable yogurt (either set or stirred). It is common for pigments like TiO2 to be added to HIPS to improve the package’s look and offer some light barrier.

- Laminated materials are preferable for pasteurized, spoonable yogurt products because they have a longer shelf life.

In this comprehensive guide, we have explored the intricacies of milk and milk product contamination, spoilage, prevention, and packaging methods. By implementing best practices and staying vigilant at every step of the journey, we can continue to enjoy the goodness and nourishment that milk and milk products offer.

Learn more:

References

- “Contamination, Preservation, and Spoilage of Milk and Milk Products” by Thiruvalluvar University

- “Preservation and Spoilage of Milk and Milk Products” by Microbiology Note

- “Spoilage of Milk and Milk Products” by Mugberia Gangadhar Mahavidyalaya

- “Unit 15” from Egyankosh

- “Contamination, Preservation, and Spoilage of Milk Products” on Prezi

- “Sources of Microbial Contamination of Milk and Milk Products” by Bihar Agricultural University

- “Spoilage of Different Products” on HMHub