Vitamin B12, also known as Cobalamin, is one of the eight Vitamins B. It is water-soluble which plays a vital role in the normal functioning of the brain and nervous system as well as in the formation of blood.

Source of Vitamin B12

It is mainly obtained from microorganisms. For Human it is obtained from meat, fish, dairy products and ruminant can obtain from the fore gut.

Daily Requirement

The Reference Daily Intake (RDI) is about 2.4 mcg and little higher consumption is required for pregnant woman as well as breast feeder.

Deficiency may cause Pernicious anemia (not enough healthy red blood cells). Strict vegetarians are at the risk of its deficiency, as the food of non-animal origins is free from cobalamine unless contaminated by bacteria.

Microbial Production of Vitamin B12

- Woodward and Eschenmoser achieved the full composition of Vitamin B12finally after 10 years of work with more than 100 researches in 1973 (Eschenmoser in 1974). The chemical production is excessively challenging in principle and costly too.

- Some of the bacteria associating with the production of B12 are Aerobacter, Agrobacterium, Alcaligenes, Azotobacter, Bacillus, Clostridium, Salmonella, Corynebacterium, Flavobacterium, Micromonospora, Mycobacterium, Nocardia, Propionibacterium, Protaminobacter, Proteus, Pseudomonas, Rhizobium, Serratia, Streptomyces, Streptococcus, and Xanthomonas.

- These vitamins are entirely manufactured through the biosynthetic fermentation process with the help of handpicked and genetically optimized micro-organisms.

- Then treat the suitable micro-organism with mutagenic agents like UV light, ethyleneimine, nitrosomethyluretane, or N methyl-N′-nitro-N-nitrosoguanidine, and the strains are selected that have high efficiency, genetic durability, reasonable growth rates, and endurance against high concentration of toxic intermediates present in the medium.

- Due to these reasons, Propionibacterium shermanii and Pseudomonas denitrificans strains are used for the industrial production of Vitamin B12. However, P. denitrificans are widely used and, it is believed that we can achieve 300 mg/l of efficiency while using P.denitrificans.

- The whole fermentation process in the case of P.denitrificansis oxygenated for 2-3 days at 30 °C while maintaining the pH values at 6-7.

- Then, Cobalt ions and DMBI was added to the medium because these compounds result in efficient biosynthesis of Vit B12.

- The potential precursors ( such as Betaine and Choline) is further added to the medium in order to have favorable effects in activating some biosynthetic stages or altering the membrane permeability.

- Vit B12 is extracted by normally heating the liquid dissolution of gathered cells for 10–30 min at 80–120 °C, at a pH value of 6.5–8.5. Finally, the heated liquid dissolution is converted into cyanocobalamin (Vitamin B12) by treating it with cyanide or thiocyanate.

Product Recovery

There are various steps involved for recovery and purification that is very important to understand in case of the fermentation products for their commercial success.

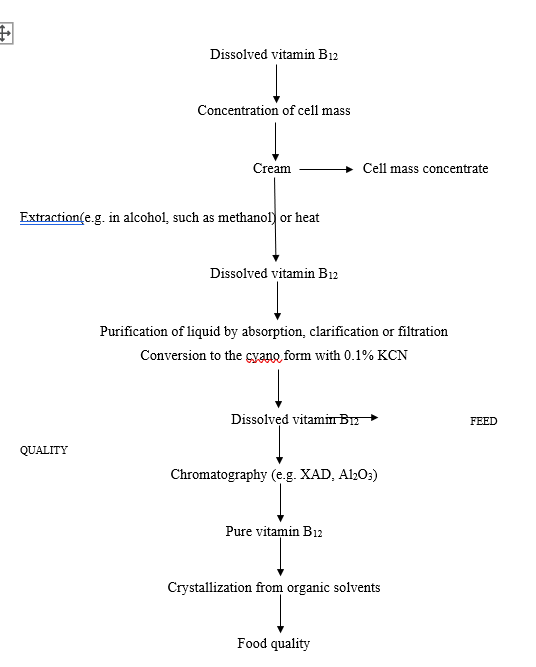

These steps involve the extraction, membrane filtration, and absorption. We normally use Adsorptive separations at the ground level processing for the recovery using different interactions such as ionic, hydrophobic, affinity, etc. The product recovery of vit B12 involvesfollowing downstream processing shown below:

A cell mass concentrate is obtained and then dried after separating the biomass through centrifugation. Alternatively, it can also be concentrate or spray dry the overall matter of the fermentor i.e. through Cell lysis (heat the spinning cell mass in an aqueous solution), or by other methods to get corrinoids.

After this, potassium cyanide is added to the availability of sodium nitrite and heated to convert corrinoids to vit B12 (cyanocobalamin). After that, the vitamin solution is refined to obtain product purity of 80% appropriate for use as an animal food additive, through filtration or treatment with zinc chloride, and then precipitation out with the addition of tannic acid or cresol.

Purification

The Vitamin B12 obtained is not pure and must be treated with Zinc hydroxide and precipitated by adding helper compounds like tannic acids or cresol. There are a number of factors that affect the degree of purification means of Zinc hydroxide such as the relative percentage of vitamin B12 active substances and pollutants present in the starting concentrate, the nature of pollutants which are present, and the method of filtrating the solution with zinc hydroxide.

The solutions of vitamin B12 active substances are prepared after the zinc hydroxide treatment to prepare concentrates appropriate for use as animal feed supplements and recover pure crystalline vitamin B12 whenever required.

The obtained vitamin B12 is purified through various extraction steps using organic solvents (like cresol, carbon tetrachloride, and water/butanol) that are complemented by absorption to ion exchangers or activated carbon. Finally, we obtain crystallized vit B12 of appropriate quality by the addition of organic solvents (such as phenol and water), for food and pharmaceutical uses.

Notes:

Vitamin B12 is widely used in medical and food industries and microbes produce vitamin B12 via a complex pathways. We use strains such as P. denitrificans and P. shermaniito to produce Vitamin B12through microbial fermentation.

However, due to the large yield of Vitamin B12, P. denitrificans are commonly used. The fermentation process is complex, strain engineering is centered on orthodox approaches because very few genetic tools are available for these strains.

Due to these reasons, it is very important to establish new engineering tools for controlling such strains. Synthetic biology and metabolic engineering strategies, as well as other traditional strategies, can also be applied for providing supervision for the fabrication of microbial cell factories for vitamin B12 production. Hence, it can further improve microbial vitamin B12 production by using these strategies on the basis of clear knowledge of the vitamin B12 metabolism in microbes.

References

- Arnold J. Holland, Penn Laird (1951), Vitamin B12 PurificationProcess

- Ichiro Kojima, Kouji Komiya, Hiroshi Sato, YutukaOguchi (1983), Process for producing vitamin B12 by the fermentation technique, and vitamin B12-producing microorganism.

- C. Spalla, A. Grein, L. Garofano& G. Ferni (1983), Microbial Production of Vitamin B12

- J.-H. Martens · H. Barg · M.J. Warren · D. Jahn (2001), Microbial production of vitamin B12

- Shrikant A. Survase, Ishwar B. Bajaj and Rekha S. Singhal (2006), Biotechnological Production of Vitamins

- Huan Fang, Jie Kang, Dawei Zhang (2017), Microbial production of vitamin B12: a review and future perspectives