Streptomycin production is a process used for producing the antibiotic streptomycin from a strain of actinomycetes. The large-scale manufacture of streptomycin utilizes Streptococcus griseus and makes advantage of the carbon, nitrogen, mineral sources, etc. present in the fermentation medium.

It has a strong inhibitory effect on gram-positive bacteria including the tuberculosis-causing Mycobacterium tuberculosis.

Streptomycin was developed by Schatz Bugie and Waksman in 1944, and one of their original soil, S. griseus isolates was used today.

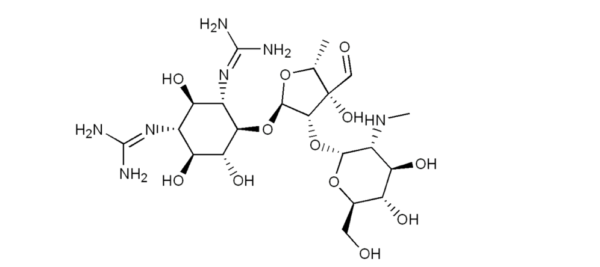

Chemical structure of streptomycin

Due to the fact that streptomycin and dihydrostreptomycin are basic substances, they are typically produced as salts.

Streptomycin can be found as the hydrochloride as crystalline HCl double salt with calcium chorial or as phosphate or sulfate, and dihydrostreptomycin can also be found in these forms.

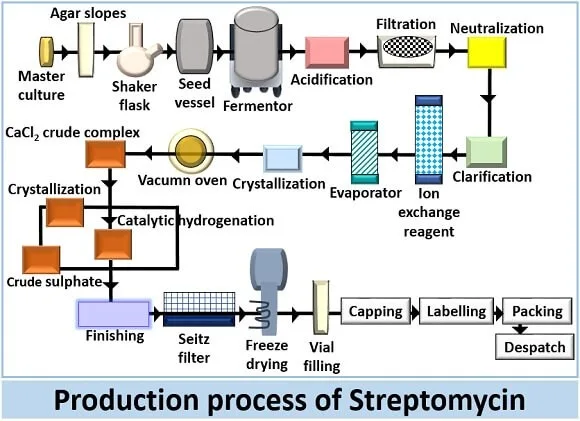

Production process of streptomycin

Preparation of medium

Hockenhull nutrient medium with the following media composition is needed to produce streptomycin.

- Glucose 2.5%

- Extracted soybean meal- 45.

- NaCl -0.25%

- Ph- 7.3-7.5 before sterilization

- Streptomycin yields in production fermenters respond strongly to high aeration and agitation.

- Optimum temperature 25-30°C.

- Optimum pH ranges from 7 and 8.

- Fermentation lasts approx. five to seven days.

- Streptomycin yields probably in excess of 1200 mg per milliliter.

For the production of the medium, there must be energy sources like carbon, nitrogen etc.

Carbon source:

Glucose, a monosaccharide, is the optimum carbon source for streptomycin production. Fructose, maltose, starch, and other sugars can also be utilized as a carbon source, but oligo- and polysaccharides produce poor yields.

Nitrogen source:

The nitrogen source is provided by ingredients like soy meal, meat extract, ammonium salts, etc.

Growth stimulating source:

Sources that promote growth include phenylacetic acid and L-naphthalene acetic acid, which are used in the synthesis of streptomycin.

Mineral source:

Sulphates, phosphates, and chlorides are minerals that are found in magnesium, calcium, potassium, and other components.

Along with the supplies mentioned above, substances including proline, oils, fatty acids, and antioxidants are also employed to hasten the generation of streptomycin. The precursors are not necessary for the manufacture of streptomycin.

Fermentation

Sterilize all the above contents and fed into the stirred tank fermenter. Then add the 4-5% of the bacterial inoculum to the medium. Keep the fermenter’s temperature between 25 and 30 degrees Celsius and its pH between 7.6 and 8. Continuous fermentation is required for the generation of streptomycin, while ongoing agitation and aeration are necessary for S. griseus growth.

Fermentation takes 4 to 10 days to complete. There are three steps to the fermentation process.

- First phase: The S. griseus releases ammonia during the early phase of growth by using soya meal to participate in proteolytic activity. During this phase, the pH rises. The carbon source in the soy meal and the glucose are slowly metabolized by S. griseus, which slows down the production of streptomycin.

- Second phase: After the consumption of soy meal and glucose, ammonia is released, and streptomycin is quickly produced. The incubation period in this phase lasts from 24 hours to 6-7 days. During this period, the pH stays steady around 7.6 to 8. There is little or no production of mycelium.

- Third phase: When the medium’s glucose concentration reaches its lowest point during the fermentation process, streptomycin production stops and the bacterial cells start to lyse. As a result of the ammonia that is deposited in the medium after cell lysis, the pH of the media rises. Harvest the fermentative medium before cell lysis so that it can be recovered and purified.

Recovery of streptomycin

The following steps are involved in streptomycin recovery:

Filtration:

Filtration is the process of removing the bacterial biomass from the fermenting broth in order to recover streptomycin. The leftover liquid is filtered, acidified, and then neutralized after filtering.

Adsorption:

In a set of three adsorption tanks, combine the activated carbon with the clear broth that was obtained after filtering. To get rid of contaminants, separate the streptomycin from the broth.

The used broth is then removed from the broth by the pressure filter once it has been fed to it. To get rid of contaminants, wash the absorbate with diluted alcohol.

Elution:

Using the ion exchange method, elute the streptomycin by adding diluted hydrochloric acid. This procedure cleans the solution of contaminants like metallic salts that could contaminate the streptomycin.

Concentration:

Use a series of three single-phase evaporators to concentrate the remaining solution at 60 degrees Celsius under vacuum.

Crystallization:

Streptomycin must first be dissolved in methanol before crystallization can take place. After that, add acetone to the filtrate to create a precipitate. The precipitate should be rinsed again with acetone and then dried under a vacuum.

Final operations: It includes the following steps like:

- The streptomycin crystals should next be dissolved in the pyrogen-free water solution.

- To get rid of the bacteria that could contaminate the streptomycin, run the solution through a special biological filter like a Seitz filter.

- The filtrate should next be dried in a vacuum to create a dried cake.

- Crush the dried cake into a powdered form by employing high vacuum sublimation using sterile steel balls.

- Then measure the streptomycin powder into sterile containers. The entire procedure must be carried out in an air-conditioned room with ultraviolet lamps that supply filtered or stale air.

- Finally, package the powdered streptomycin in the rooms having 10% relative humidity.

Uses of streptomycin

The main purpose of the antibiotic drug streptomycin is to treat bacterial infections. It was a common practice in the past and one of the first effective therapies for tuberculosis. However, because to the emergence of antibiotic resistance and the accessibility of substitute antibiotics with fewer side effects, its use has been more constrained. Here are a few modern and traditional use for streptomycin:

- Treatment of Tuberculosis: Streptomycin has historically played a significant role in the treatment of tuberculosis (TB). It was one of the first medications that worked against the TB-causing bacterium Mycobacterium tuberculosis. Due to concerns about antibiotic resistance and the use of alternative antibiotics like rifampin and isoniazid, it is now used less frequently to treat TB.

- Other Mycobacterial Infections: In addition to treating tuberculosis (TB), streptomycin may also be used to treat infections caused by the Mycobacterium avium complex (MAC).

- Plague: Streptomycin is sometimes used to treat the plague, which is carried on by the bacteria Yersinia pestis and includes both bubonic and septicemic plague. If used quickly, it can be useful in halting the disease’s spread.

- Tularemia: Streptomycin can also be used to treat tularemia, an uncommon infection brought on by the Francisella tularensis bacterium.

- Brucellosis: Streptomycin may occasionally be used to treat brucellosis, a bacterial infection brought on by different types of the Brucella bacteria.

- Bacterial Endocarditis: To treat bacterial endocarditis, an infection of the heart’s inner lining or valves, streptomycin may be used with other medicines.

- Agricultural science: Streptomycin is used as a “Pesticide” that inhibits the growth of bacteria, fungi, algae, and other organisms.

- Protein purification: Streptomycin sulfate is sometimes added to the process of purifying proteins from biological extracts in order to remove nucleic acids.

Harmful effect of streptomycin

Although streptomycin is an antibiotic that can be used to treat some bacterial infections, it also has the potential to cause negative side effects. It’s crucial to remember that not everyone will experience these side effects, and that each person will experience them to a different degree. The following are some adverse reactions and side effects of streptomycin:

- Hearing Loss (Ototoxicity): One of the most serious and well-known adverse effects of streptomycin is the chance for hearing loss (ototoxicity). Higher doses are typically more likely to result in hearing issues because this side effect is typically dose dependent. Both temporary and permanent hearing loss are possible.

- Kidney Damage (Nephrotoxicity): Streptomycin can also impact the kidneys, which could result in kidney damage (nephrotoxicity). During treatment, kidney function should be checked.

- Balance and Vestibular Problems: Streptomycin can have an impact on the vestibular system in the inner ear, causing balance issues, vertigo, and dizziness.

- Allergic Reactions: Like any medication, streptomycin can cause allergic reactions in some individuals. Signs of an allergic reaction may include rash, itching, swelling, severe dizziness, and difficulty breathing.

- Gastrointestinal Discomfort: While using streptomycin, some persons may develop nausea, vomiting, diarrhea, or other gastrointestinal discomfort.

REFERENCES

- Essentials of Industrial Microbiology. Retrieved from https://foodtechnotes.com/wp-content/uploads/2020/06/Essentials-of-Industrial-Microbiology.pdf

- Production of Streptomycin. Biology Reader. Retrieved from https://biologyreader.com/production-of-streptomycin.html

- Streptomycin: Chemical Structure, Production, Recovery, and Uses. Microbiology Notes. Retrieved from https://microbiologynotes.org/streptomycin-chemical-structure-production-recovery-and-uses/

- Industrial Biotechnology – Lecture 28. Rama University. Retrieved from https://www.ramauniversity.ac.in/online-study-material/faculty_sciences/bscbiotechnology/vi-semester/industrialbiotechnology/lecture-28

- Streptomycin Production Process. Google Patents. Retrieved from https://patents.google.com/patent/US2504067A/en

- Journal Article PubMed. Retrieved from https://pubmed.ncbi.nlm.nih.gov/18054224/