Fermented alcoholic beverages are quite popular worldwide since thousand years for the purpose of drinking, entertainment, refreshment, nourishment and for religious purpose as well.

It provides thirst relief and refreshment to the body when body loses liquid due to physical activities. Similarly, nutrients available in drinks during fermentation provides nourishment to the body and some customs and religions have tradition on drinking local fermented drinks as well.

Alcohol fermentation is one of the type of fermentation among four types. Other includes lactic acid fermentation, acetic acid fermentation and alkali fermentation which takes place in their own respective products.

During the fermentation process, the bacteria and yeast hydrolyzes the starch and sugar materials and convert it into ethanol, organic acids and carbon dioxide.

Additionally, fermentation also provides in volume reduction of raw materials especially during transportation and preservation and also increases aesthetic values and shelf life for consumption.

Health benefits of fermented drinks:

Fermented beverages helps in improvement of gut health and suppresses the growth of pathogenic stomach cancer causing bacteria, Helicobacter pylori.

Ethanol helps in detoxification of carcinogenic compounds from the body and strengthens the immune system.

It also supplies essential nutrients such as Vitamin B, riboflavin, folic acid, biotin, niacin, thiamine, aminoacids, proteins and lactic acid to the body.

It is also believed that fermented beverages reduces the symptom of rheumatoid arthritis.

Some common alcoholic beverages include:

- Chhyang

- Rakshi

- Jaand

- Japanese sake

Methodology of fermented alcoholic beverages in traditional process

Chhyang/Jaand Preparation:

- Take about 500gm of glutinous rice, wash, soak and cook for an hour.

- Cool the rice and add 5gm of murcha and mix properly with 1 litre of water.

- Transfer the rice into clean container and cover it with muslin cloth.

- Leave for fermentation at room temperature approximately for 7 to 14 days.

- Mash and drain for the white liquid.

- Chhyang/Jaand gets ready to drink.

Microbiology of Chhyang/Jaand:

Fermentative yeasts, saccharifying mold and lactic acid bacteria carries out the fermentation in two steps:

Saccharification and liquefaction of starch

- Lactic acid bacteria utilizes simple sugar into ethanol, organic acids and carbon dioxide.

- A fruity smell develops after 2-3 days of fermentation which is developed by P. anomala.

- Total mesophilic count increases during 5 days of fermentation whereas mold count decreases.

- After anaerobic fermentation for 8 days, liquefaction occurs and fermentation completes by yeasts such as S. cerevesiae, C. glabrata, S. fibuligera which increases rapidly.

- Similarly, lactic acid bacteria such as P. pentosaceus and L. bifermentans and mold like Mucor and Rhizopus completes the saccharification.

Biochemical changes

- At the end of the process, pH decreases whereas acidity increases.

- Alcohol concentration rises upto 4-11%

- Calorie content also increases from 3-5kcal/g

- Increment in thiamine, pyridoxine, folic acid and niacin.

Rakshi Preparation

- Usually reddened rice known as Hakuwa is taken for the preparation of rakshi as a substrate.

- Reddened rice is made by stacking the fresh paddy in the same plant and covering it for 8-10 days where color change can be observed.

- For rakshi, take atleast a year old reddened rice and soak in water for 12-24 hours.

- Drain and cook the rice completely in a clay pot.

- Spread the cooked rice in a clean surface and let it cool.

- After cooling at room temperature, mix the rice with mana (a powdered starter culture) in a clay pot or container and add water in the mixture with 1:1:3 ratio (rice/mana/water).

- Air tight the container and cover with a muslin cloth and leave for fermentation for about 3 months in a cold and dark place.

- Microbiology of rakshi is as same as jaand where the fermentative yeasts, saccharifying mold and LAB completes the fermentation.

Biochemical changes

- pH drops and acidity increases of the brew.

- After 5 weeks of fermentation, alcohol concentration can be obtained up to 11 to 13%.

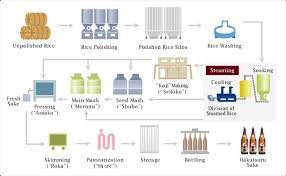

Japanese Sake preparation

- Take a short grain variety of rice, wash and soak for about 15-20 hours depending upon the inflexibility of rice.

- Drain the excess water and steam the rice for 30-60 mins and cool at room temperature.

- Add koji i.e, starter culture of yeast S. cerevisiae with water and mix well.

- Leave for fermentation for 2-3 weeks at 15-20°C.

- To obtain high grade Sake, lower the temperature below 10°C so that the fermentation delays.

- Filter the liquid with carbon paper and dilute with water to lower the alcohol content.

Microbiology of Japanese Sake

- In early fermentation, S. cerevisae and nitrate reducing bacteria converts nitrate into nitrites which inhibits the growth of other contaminating microorganisms.

- Lactic acid bacteria such as L. plantarum and L. sakei takes the process till end.

Biochemical changes

- Chemical components like ethyl corporates, isoamyl acetate gives a fruity aroma during sake brewing.

- Alcohol content can be obtained upto 18-20%.

Refrences:

- Kaur, P., Ghoshal, G., & Banerjee, U. C. (2019). Traditional Bio-Preservation in Beverages: Fermented Beverages. Preservatives and Preservation Approaches in Beverages, 69–113.

- http://www.ijrpb.org/papers/v5-i5/3.pdf

- https://www.tandfonline.com/doi/full/10.1080/09168451.2015.1095067

- https://www.intechopen.com/books/food-industry/sake-alcoholic-beverage-production-in-japanese-food-industry